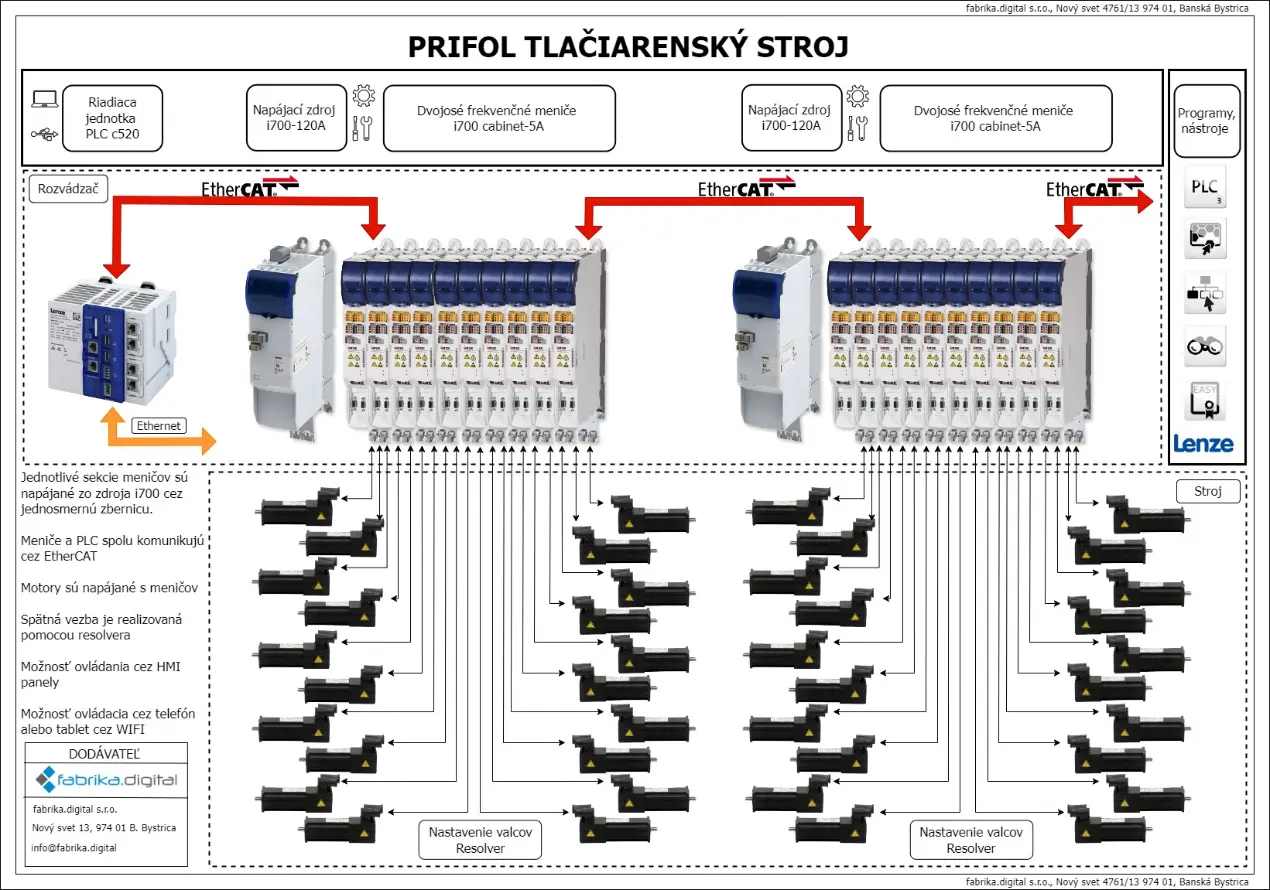

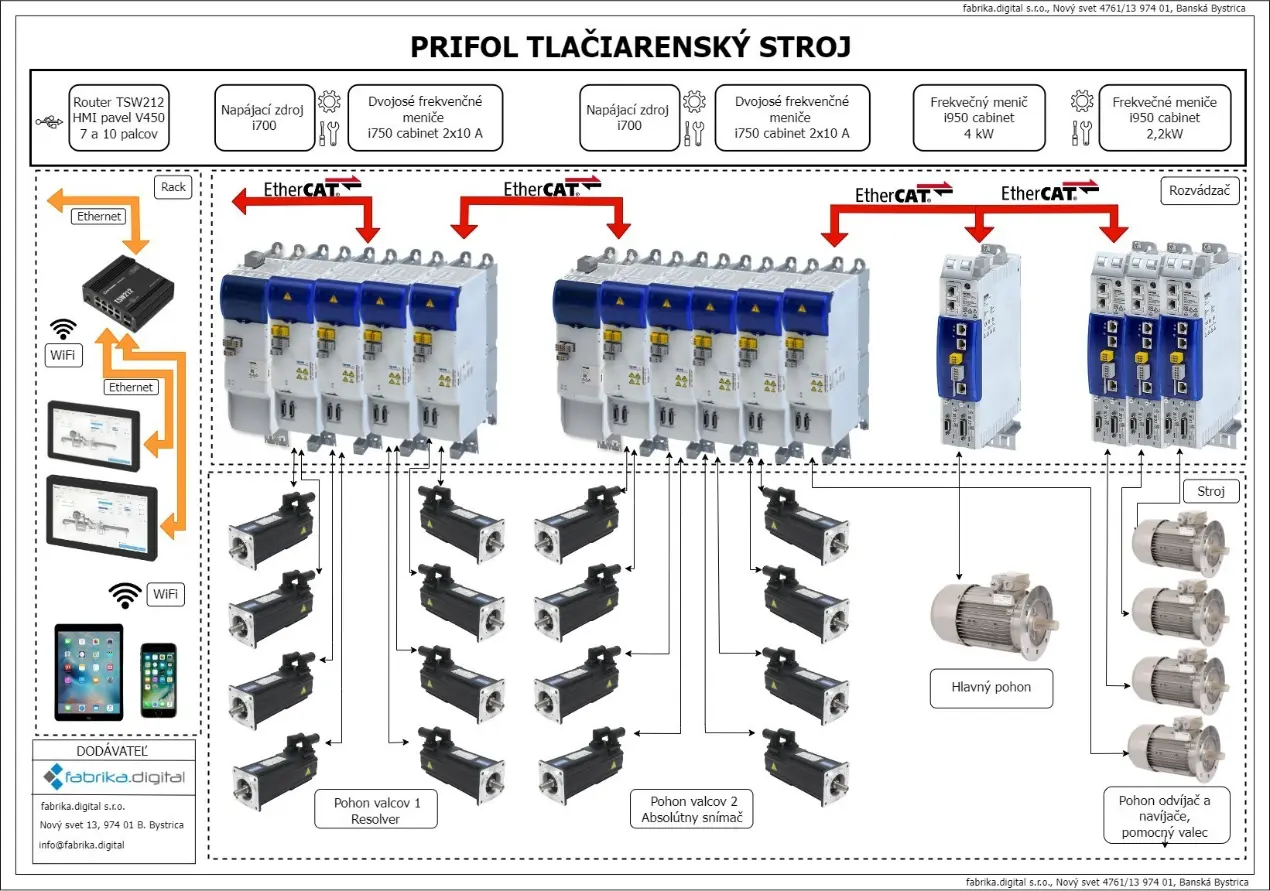

Complete modernization of a printing machine with the implementation of a Lenze automation system

The scope of the project involved a comprehensive modernization of an older eight-color printing machine whose original control system suffered from frequent failures, unstable communication, and a high level of unplanned downtime. The objective was a complete migration to a modern Lenze automation platform in order to increase reliability, serviceability, and technological accuracy of the equipment. The machine was based on a central impression cylinder acting as the main synchronized drive of the entire line. The individual colors were divided into 8 sections, each containing 7 controlled drives. The machine also included an unwind and rewind section equipped with 4 drives. The technological equipment was complemented by heating ovens and fans ensuring proper drying and process stability. The total number of machine axes was 62, making it a highly complex modernization project.

CUSTOMER REQUIREMENTS

- Replacement of the existing control system with a new Lenze platform (C520) and complete reprogramming of the printing machine

- Replacement of existing Lenze 9300 frequency inverters with new drive units

- Replacement of the legacy CANopen communication with a new EtherCAT network

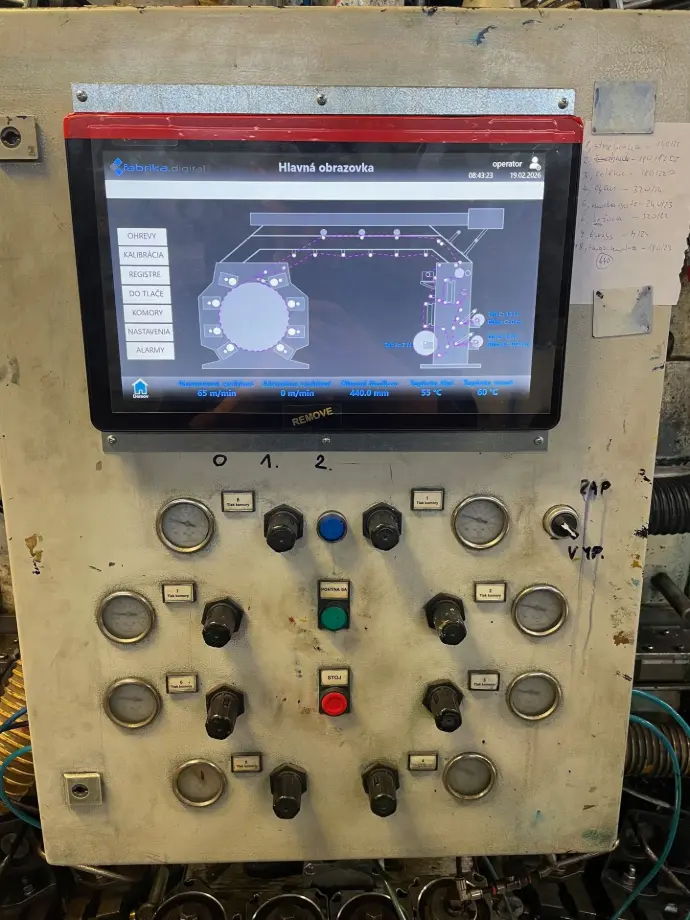

- Installation of new Lenze v430 HMI panels, development of a new visualization interface, and implementation of remote machine control

- Modification of the safety wiring, reorganization of the control cabinet, and disconnection/removal of all unnecessary components (cabling, protection devices, chokes, power supplies, etc.).

- New electrical documentation

USED COMPONENTS

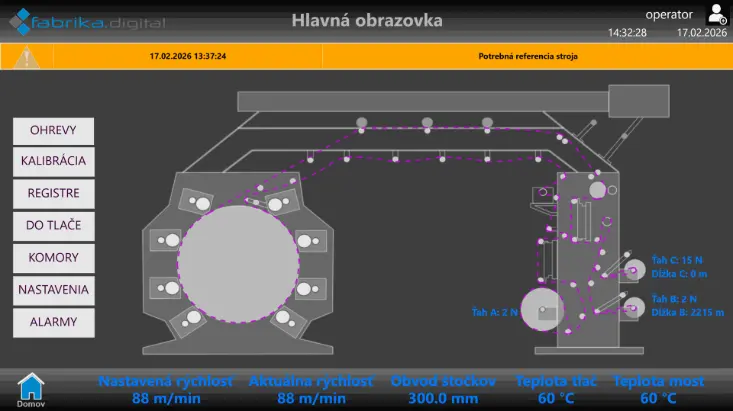

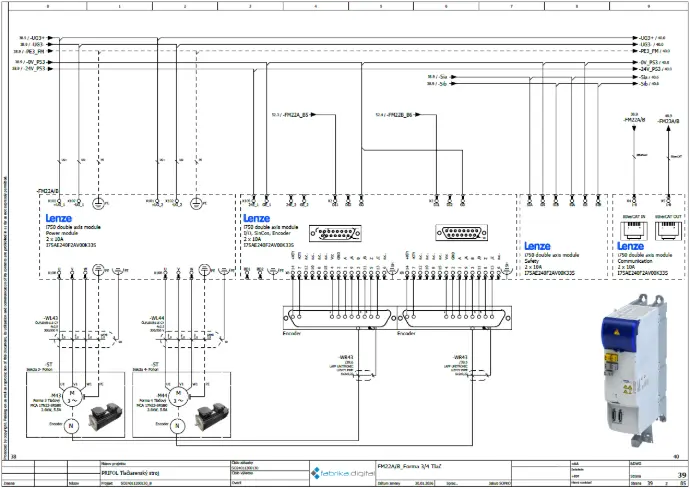

As shown in the block diagram, the control system was based on a Lenze C520 PLC. Two Lenze v430 HMI panels in 7" and 15" sizes were used for visualization and operation. Remote machine control was implemented via a mobile device with the possibility of further functional expansion. Dual-axis Lenze i700 drives were used for positioning axes, while printing and anilox rollers were controlled by dual-axis Lenze i750 drives. The advantage of these drives lies in the use of a single power supply per drive section with interconnection via a common DC bus. Drives in the unwind section were upgraded to Lenze i950 units, which were also used for the main central drive of the machine.

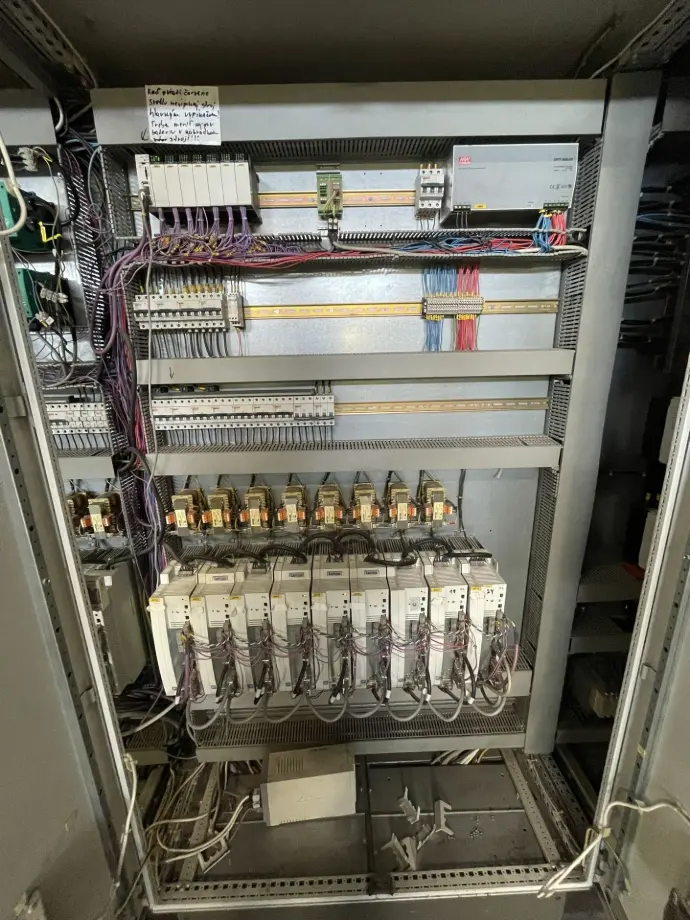

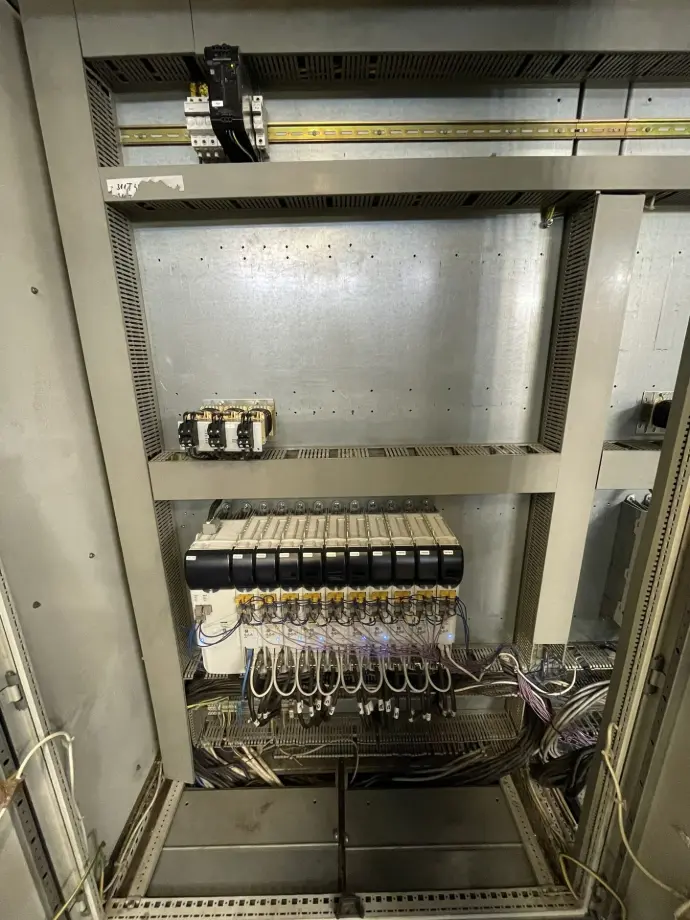

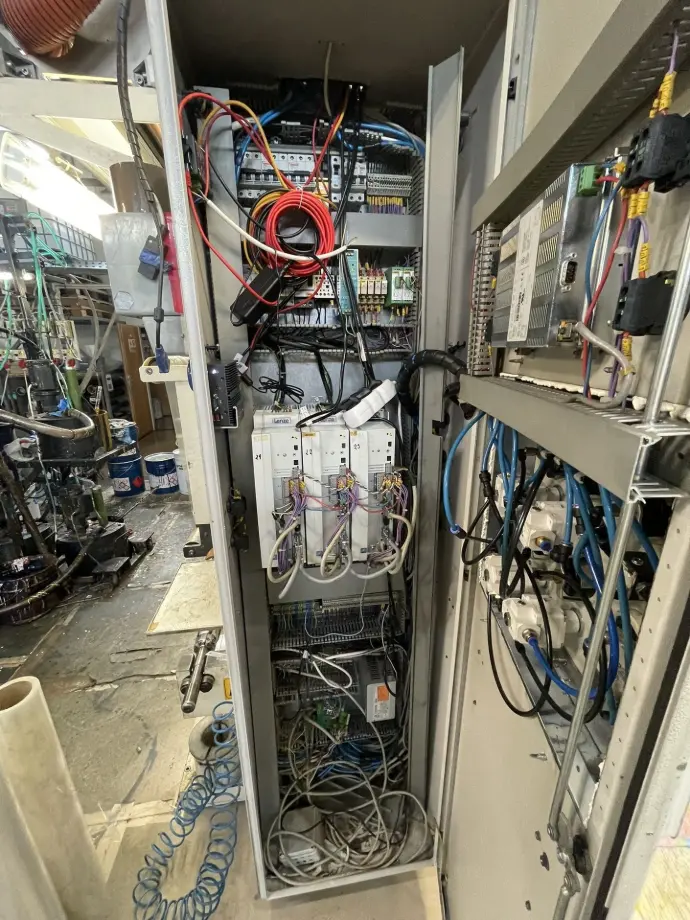

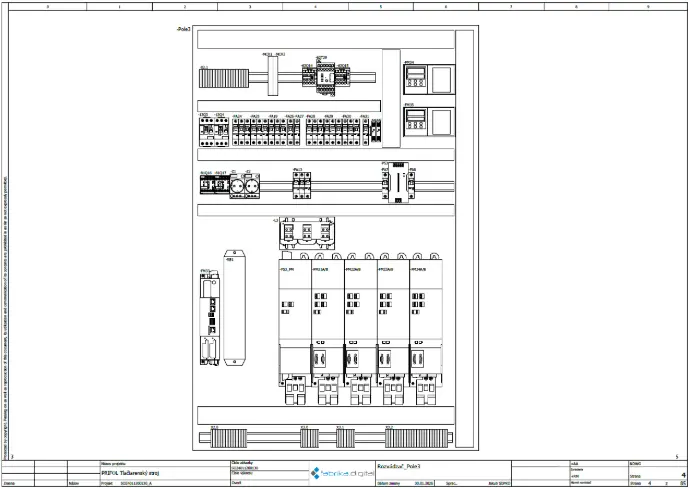

CONTROL CABINETS

As part of the modernization, the original frequency inverters installed in all control cabinets were completely replaced with new drive units. The drives were divided into four power sections according to the technological parts of the machine. By implementing Lenze i700/i750 series inverters, the power architecture of the cabinets was significantly simplified, since each section required only a single power supply unit, one line choke and one main circuit breaker, while the individual drives were interconnected via a common DC bus. This DC bus coupling also provides a positive effect on the transfer of regenerated energy during drive deceleration, reducing the overall thermal load of the system.

The original control system consisting of two PLCs was replaced by a single Lenze C520 PLC together with distributed I/O modules. The CANopen communication bus was replaced by a deterministic EtherCAT network, resulting in higher control speed and improved reliability. During the reconstruction, all unused components were removed from the cabinets, the safety architecture was simplified, and the overall wiring layout was optimized. As a result, both cabling complexity and service accessibility were significantly improved compared to the original installation.

From a hardware architecture perspective, the machine was divided into three main control cabinets:

• Main cabinet - containing four sections of Lenze i700 and i750 drives, an i950 inverter for the main central drive, additional drives for heating fans and heaters, as well as protection and power distribution components.

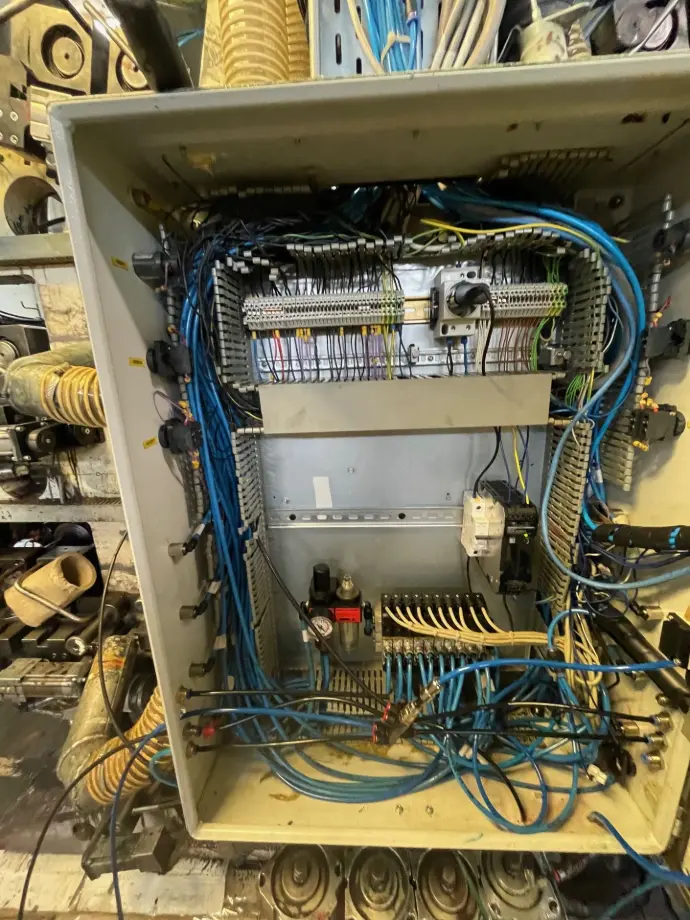

• Winder and unwinder cabinet - dedicated to tension control and regulation of winding and unwinding processes. This cabinet includes three Lenze i950 drive units.

• Control cabinet - housing pneumatic control valves, operator pushbuttons and the main HMI panel.

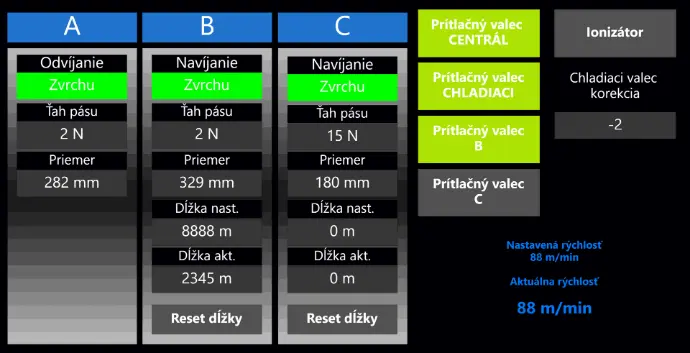

For simplified machine setup and operation, a remote control solution was also delivered. This consisted of a mobile phone with an independently developed visualization interface. The “controller” is used for adjusting individual printing sections, fine-tuning slip parameters and setting the pressure against the main cylinder. Thanks to the wireless connection, the operator is able to configure the machine from virtually any position, including directly from behind the inspection camera monitoring the printing process.

PROGRAMMING

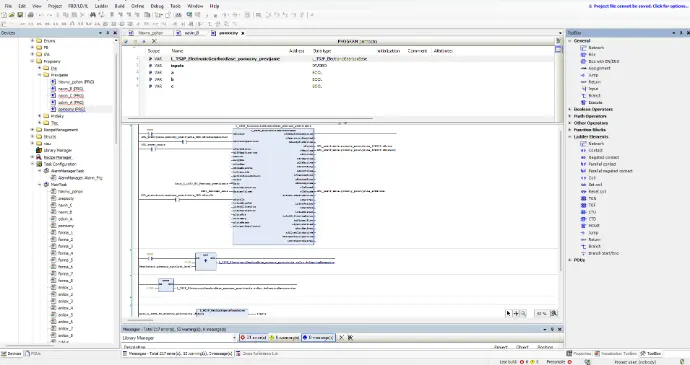

As part of the modernization, the control system was completely reprogrammed in the Lenze PLC Designer environment, where a new motion-control architecture based on a master-slave drive synchronization concept was implemented. The industrial EtherCAT fieldbus was implemented as the communication infrastructure between the individual parts of the control system, ensuring deterministic real-time data exchange between the PLC, drives and distributed I/O modules. The initial step of the implementation involved precise configuration and recalculation of the incremental encoder pulses of the main cylinder, which serves as the reference axis for the entire technological process. Based on this reference value, all remaining drives were subsequently synchronized.

After successful testing of the winding and unwinding process, the implementation of the printing control itself followed. The printing machine consisted of eight printing sections, each representing an individual color unit. Mechanically, each section was composed of an anilox roller and a printing cylinder, where the anilox roller meters the ink onto the printing cylinder, which then transfers the image directly onto the foil guided over the main central impression cylinder.

From a motion-control perspective, each printing section was designed as an independent multi-axis system. Both the anilox roller and the printing cylinder were equipped with a pair of positioning drives for radial movement towards and away from the main cylinder, allowing precise adjustment of pressure and working distance during technological operation. The printing cylinder was additionally equipped with a dedicated linear drive for axial movement, used for fine lateral register correction (left–right) during machine operation. In total, each printing section included seven controlled drive axes.

From a synchronization perspective, the printing cylinders had to be precisely synchronized with the main cylinder in order to eliminate print smearing caused by phase shifts or speed instability. During programming, the Lenze FAST Sync & Correction block was used for this purpose. It is an application motion module designed for accurate axis synchronization and dynamic position correction during machine operation. It is mainly used in printing, packaging and converting lines, where multiple drives must follow a reference (master) axis while still allowing fine adjustments without interrupting production.

For the anilox rollers, precise synchronization was not required; they operated in speed mode as subordinate axes, following the speed of the printing cylinders. As part of the implementation, a homing sequence was also programmed to define the machine’s base technological position. Once the reference cycle was initiated, all axes automatically moved to their initial positions. For both the printing and anilox rollers, this meant rotating to the upper angular position, allowing simple and safe installation of printing plates and easier handling of printing components.

The drives responsible for the radial movement of the rollers and for adjusting the printing gap performed their homing procedure based on position sensors. Each axis had a precisely defined reference point derived from the sensor, which established the zero position for subsequent technological movements.