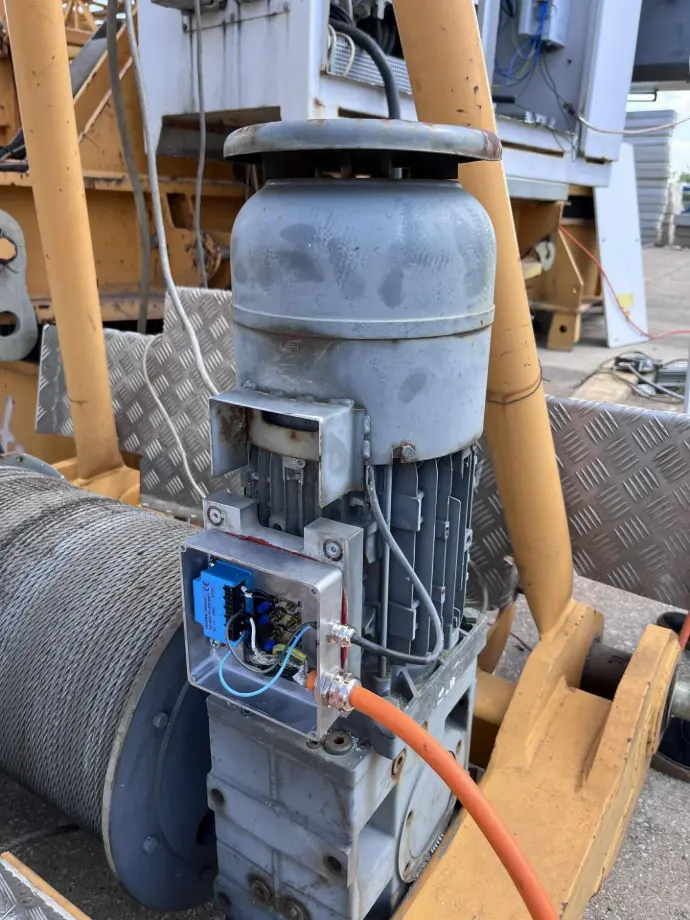

It was a large overhead construction crane, where the customer’s requirement was to modernize the original drive for the load travel in the X-axis (forward/backward along the crane bridge). Originally, a decentralized frequency inverter was installed directly on the motor housing. This system had to be replaced with a new solution, in which the frequency inverter was relocated into the main crane switchgear. The drive provided load movement in both directions with the possibility of operation at three different speed levels.

CUSTOMER REQUIRMENTS

- Ununstalling of the old frequency inverter from the motor

- Installation of the new frequency inverter into the switchgear cabinet

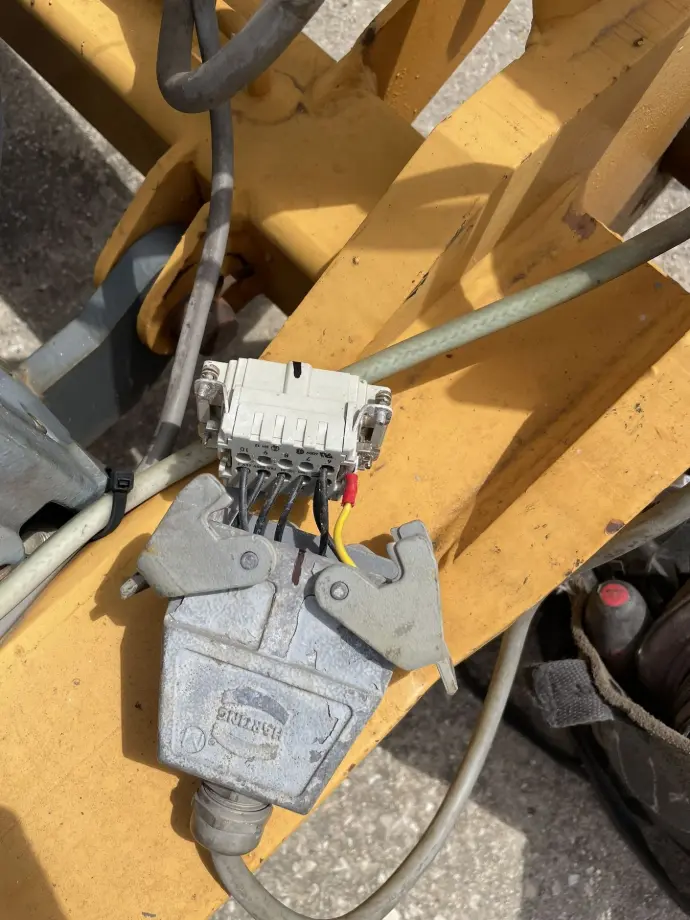

- Replacement of the power and control cabling between the inverter and the motor

- Programming and commissioning