Modernization of pipe cutting equipment with Lenze automation system

The pipe cutting unit is an integrated part of the extrusion line for plastic pipes. The cutting system automatically captures the extruded pipe and accurately cuts it to the required lengths during continuous production – without the need to stop material movement. The cutting cycle is synchronized with the pipe feed rate using a servo drive.

CUSTOMER REQUIRMENTS

- Replacement of the control unit, frequency inverters and HMI panels

- Complete reprogramming of the cutting unit

- Development of a new control visualization interface

-

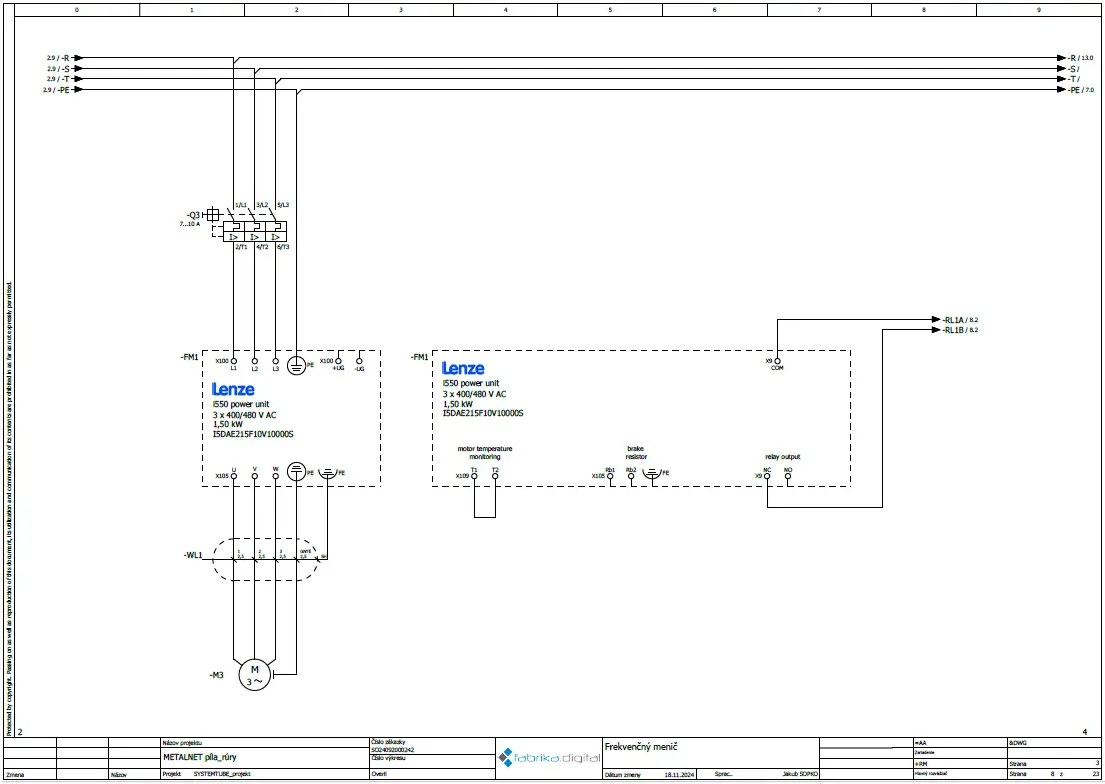

New electrical schematic reflecting the current wiring layout

PART OF ELECTRICAL DIAGRAM

CONTROL SYSTEM PROGRAMING

As part of the machine modernization, a completely new control system was developed, including the design of a new HMI visualization interface for the machine operator. The control program ensures synchronized movement of the sliding carriage with the speed of the produced material, followed by pipe clamping, activation of the cutting unit, and engagement of the auxiliary extraction system to remove plastic chips generated during the cutting process.

The visualization interface includes two operating modes – automatic and manual. In manual mode, all functional components of the cutting unit can be controlled individually, which is primarily used for setup and maintenance purposes. In automatic mode, the operator enters the required lengths and number of pieces into a table, based on which the machine operates fully autonomously without the need for operator intervention.

As mentioned above, one HMI panel is mounted directly on the door of the cutting unit’s control cabinet, while the second is installed at the beginning of the production line near the extruder, allowing the operator to monitor the current number of cut pieces and the production status.