Kompletná modernizácia paletizátora s automatizáciou Lenze pre linku na balenie vody

Dodali sme komplexnú modernizáciu priemyselného paletizéra používaného pri výrobe fľaškovanej vody.

Projekt zahŕňal kompletnú prestavbu riadiaceho rozvádzača, inštaláciu automatizačných komponentov Lenze, integráciu bezpečnostných systémov PILZ a rozsiahle programovanie PLC.

Výsledkom sú výrazne rýchlejšie paletizačné cykly, vyššia úroveň bezpečnosti a jednoduchšia údržba.

Paletizér predstavuje flexibilné a kompaktné riešenie pre paletizáciu, navrhnuté pre rôzne priemyselné odvetvia. V tomto prípade sa využíva na usporiadanie a stohovanie fliaš s vodou.

POŽIADAVKY ZÁKAZNÍKA

- Kompletná prestavba rozvádzača (káblovanie, meniče, ochranné prvky, zdroje napájania, bezpečnosť, samotný rozvádzač, PLC, vstupy/výstupy)

- Ovládací panel (HMI)

- Prekáblovanie všetkých motorov a senzorov

- Výmena bezpečnostných prvkov (núdzové stop tlačidlá, zámky dverí, PILZ)

- Inštalácia magnetostrikčného snímača

- Kompletné preprogramovanie paletizačného zariadenia

- Zrýchlenie celého procesu paletizácie

Príprava

Špecifikovanie a objednanie všetkých potrebných súčastí

Produkcia

Výroba, montáž a zapojenie celého priemyselného rozvádzača

Testovanie

Testovanie senzorov, pripájanie motorov, PLC a frekvenčných meničov

Programovanie

Finálne programovanie, spúšťanie a ladenie stroja

BLOKOVÝ DIAGRAM

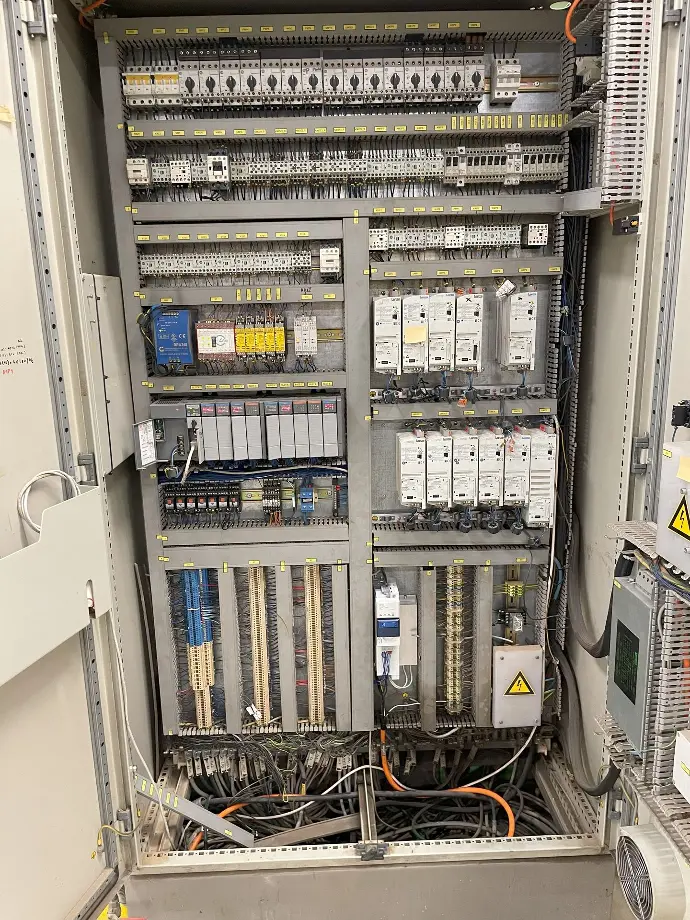

ROZVÁDZAČ

Počas kompletnej rekonfigurácie rozvádzača bol pôvodný riadiaci systém Allen-Bradley nahradený PLC systémom Lenze c520. Všetky vstupno/výstupné moduly boli modernizované na nové komponenty Lenze, čím sa zabezpečila kompatibilita a jednotná integrácia riadiacich prvkov. Komunikácia medzi jednotlivými časťami systému je realizovaná prostredníctvom protokolu EtherCAT. Pôvodné frekvenčné meniče boli nahradené novými modelmi Lenze i700, ktoré využívajú zbernicový systém a výrazne zjednodušujú inštaláciu. Tento systém umožňuje napájanie z jedného zdroja a použitie jediného ochranného prvku, čím sa minimalizuje počet bezpečnostných prvkov a zjednodušuje celkové zapojenie.

K meničom bol pridaný brzdný rezistor na elimináciu vzniku nechceného napätia na jednosmernej zbernici počas brzdenia. Bezpečnostné prvky boli realizované pomocou modulov PILZ, ktoré riadia bezpečnosť zámkov dverí, zábran a núdzových tlačidiel STOP. Celý riadiaci rozvádzač je chránený klimatizačnou jednotkou namontovanou na dverách, ktorá zabraňuje prehriatiu zariadenia.

Tento technický prístup výrazne zvýšil efektivitu, posilnil bezpečnosť a zjednodušil správu rozvádzača.

Obrázok 1. Pôvodný rozvádzač Obrázok 2. Nový rozvádzač

OVLÁDACÍ PANEL

V rámci modernizácie paletizéra bol ovládací panel kompletne prepracovaný a vybavený 10-palcovým HMI displejom Lenze V450. Tento displej bol zvolený pre svoju optimálnu veľkosť, ktorá zaručuje jednoduchú obsluhu zariadenia a výbornú čitateľnosť všetkých potrebných informácií. Modernizácia ovládacieho panela zahŕňala aj aktualizáciu softvérového rozhrania, čo zvýšilo efektivitu interakcie operátora s paletizérom a zlepšilo reakčné časy pri obsluhe.

PREKÁBLOVANIE MOTOROV A SENZOROV

V rámci modernizácie boli kompletne vymenené všetky napájacie káble pripojené k motorom, vrátane flexibilných káblov vedených v energetických reťaziach a pevných inštalácií. Paletizér obsahoval viacero senzorov, pri ktorých boli vymenené multisignálne káble s cieľom zabezpečiť efektívnu prenosovú kapacitu a spoľahlivosť signálu. Okrem toho boli motorové ovládače Motek, ktoré boli pôvodne integrované priamo na motoroch, demontované a premiestnené do riadiaceho rozvádzača. Tým sa optimalizovala prístupnosť a zjednodušila údržba celého systému

PROGRAMOVANIE

Kompletné preprogramovanie paletizátora bolo realizované v softvéri Lenze PLC Designer. Programovanie bolo rozdelené do viacerých sekcií a to: vstupných a výstupných dopravníkov, výťahu, pavúka na ukladanie preložiek, stohovacieho stola a podávača paliet. Boli vyvinuté rôzne softvérové varianty pre fľaše s objemom 0,5 l, 1,5 l a 2 l. Každá varianta bola optimalizovaná pre odlišný počet fliaš a vrstiev na palete. Okrem toho bol implementovaný nový spôsob stohovania, ktorý zlepšil viditeľnosť značky na obaloch.

Hlavným cieľom preprogramovania paletizéra bolo zvýšiť celkovú efektivitu procesu a zabezpečiť plynulejšie prechody medzi jednotlivými operáciami. Tento cieľ sa podarilo dosiahnuť skrátením časových intervalov medzi úlohami, zvýšením pracovných rýchlostí a úpravou logiky niektorých operácií.

Výrazné zrýchlenie celého procesu sa dosiahlo integráciou magnetostrikčného snímača na výťahu, ktorý umožnil presné polohovanie pri nakladaní a vykladaní fliaš aj s použitím asynchrónnych motorov. Tento snímač nahradil pôvodné indukčné snímače, ktoré často nedokázali správne detegovať polohu výťahu, čo viedlo k jeho prebehnutiu cez snímač a spôsobovalo chyby stroja. Vďaka presnému polohovaniu sa tento problém úplne odstránil a výťah mohol dosahovať podstatne vyššie rýchlosti.

Pred modernizáciou bol paletizér náchylný na poruchy a nedosahoval požadovanú prevádzkovú rýchlosť. Po generálnej prestavbe sa miera poruchovosti znížila na takmer nulovú a došlo k zlepšeniu rýchlosti, diagnostiky a odstraňovania chýb pri servise. Hlavným prínosom tejto modernizácie je dosiahnutie prevádzkových rýchlostí, ktoré plne zodpovedajú maximálnej kapacite výroby.

Poďme sa porozprávať o tom, ako môžeme zvýšiť výkon Vašej výrobnej linky.