Navíjacie zariadenie JUMBO

Navíjacie zariadenie je určené na efektívne navíjanie gumenej strešnej krytiny používanej na pokrytie budov. Pozostáva z dvoch samostatných navíjacích jednotiek, z ktorých vždy pracuje iba jedna. Druhá jednotka je pripravená na okamžité použitie počas výmeny rolky, čím sa eliminuje prestoj a umožňuje nepretržitú výrobu. Toto riešenie zabezpečuje, že stroj pred navíjačkou nemusí byť zastavený, čo zabezpečuje kontinuitu výroby.

Medzi navíjačkou a strojom je nainštalovaný akumulátor materiálu, ktorý počas výmeny roliek uchováva potrebné množstvo materiálu. Tento akumulátor zabraňuje vzniku prestojov a umožňuje plynulý prechod medzi navíjacími jednotkami.

Ťahanie materiálu je zabezpečené pomocou ťažného valca umiestneného nad navíjačkami. Rýchlosť ťahania musí byť synchronizovaná s rýchlosťou výrobnej linky aj s rýchlosťou navíjacích jednotiek, aby sa zabezpečilo optimálne napnutie materiálu. Toto napnutie je kľúčové na to, aby bol materiál správne a rovnomerne navinutý na rolku, čo zaručuje vysokú kvalitu výsledného produktu.

POŽIADAVKY ZÁKAZNÍKA

- Kompletné prerobenie rozvádzača (káblovanie, frekvenčné meniče, bezpečnosť, napájacie zdroje, nová skriňa rozvádzača, PLC, vstupy/ výstupy)

- Nový ovládací panel (HMI display, ovládacie tlačidlá, nový rozvádzačový panel)

- Výmena motorov

- Výmena starej bezpečnosti za novú (PILZ)

- Kompletné preprogramovanie navíjacieho zariadenia

- Optimalizácia navíjacieho procesu, zvýšenie efektivity výmeny roliek, eliminovanie krčenie materiálu.

Príprava

Špečifikovanie a objednanie všetkých potrebných komponentov

Produckcia

Výroba a zapojenie rozvádzača

Testovanie

Testovanie snímačov, zapojenie motorov, PLC, frekvenčné meniče

Programovanie

Finálne programovanie a nastavovanie

BLOKOVÝ DIAGRAM

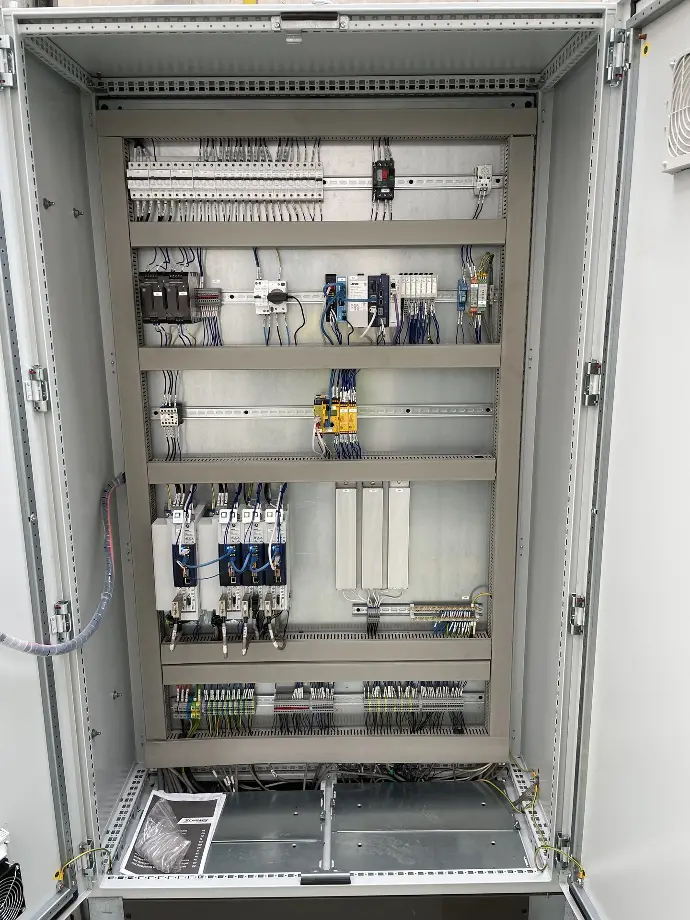

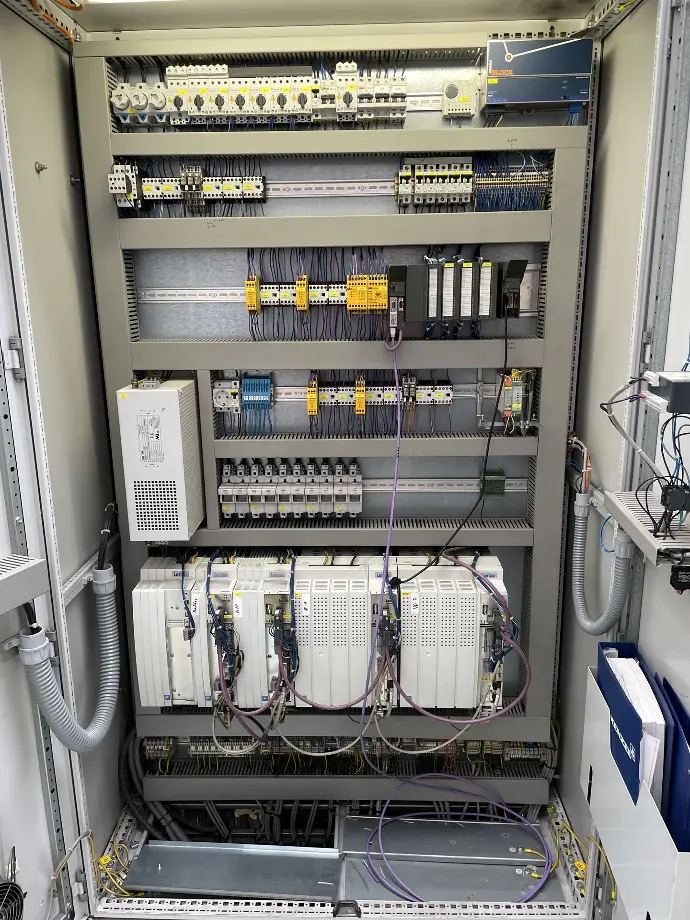

Obrázok 1. Rozvodná skriňa pred prerobením Obrázok 2. Rozvodná skriňa po prerobení

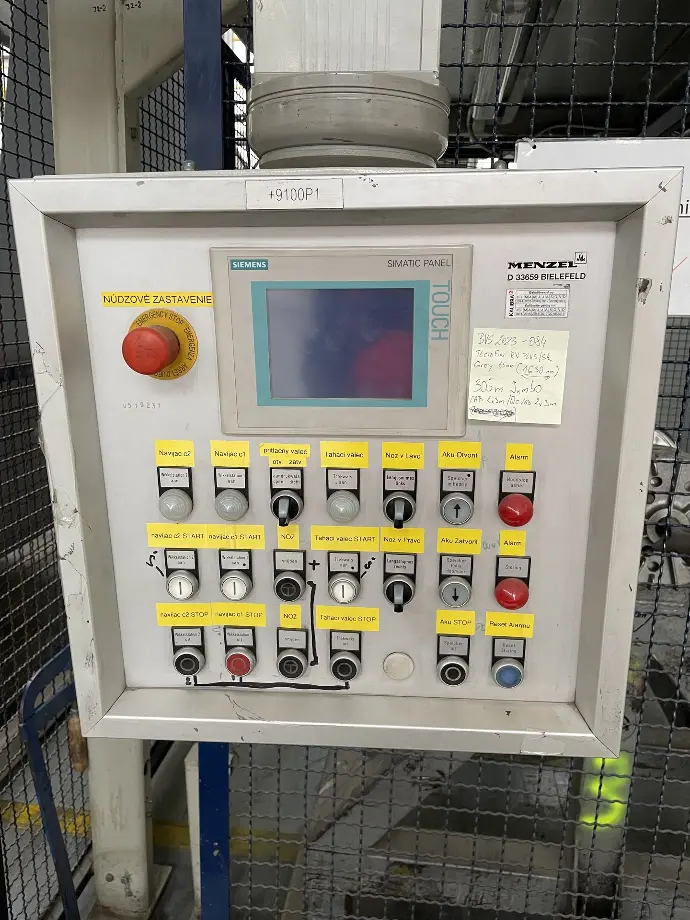

Obrázok 3. Starý ovládací panel Obrázok 4. Nový ovládací panel

VÝMENA MOTOROV A BEZPEČNOSTNEJ JEDNOTKY

V rámci modernizácie stroja boli vymenené hlavné navíjacie motory a motor ťažného valca. Táto výmena zahŕňala kompletnú demontáž starých motorov, inštaláciu nových a ich integráciu do systému. Proces výmeny motorov si vyžadoval presnú koordináciu – a to nielen pri ich fyzickom umiestnení, ale aj pri elektrickom zapojení a integrácii do riadiaceho systému. Nové motory poskytujú vyššiu účinnosť, lepšiu reguláciu výkonu a nižšiu spotrebu energie, čím prispievajú k celkovej modernizácii a optimalizácii prevádzky stroja.

Starý bezpečnostný modul Pilz bol nahradený novou, kompaktnejšou jednotkou, ktorá umožňuje komunikáciu s riadiacim systémom.

PROGRAMOVANIE

Cieľom programovania bola optimalizácia celého procesu navíjania. Bolo potrebné zabezpečiť, aby synchronizácia ťažných síl medzi ťažným valcom a navíjacími jednotkami bola konzistentná, a tak sa predišlo nadmernému napätiu alebo ochabnutiu materiálu. Ťah valca bol riadený pomocou tenzometra umiestneného na vstupe do navíjačky, ktorý poskytoval spätnú väzbu pre reguláciu sily.

Napnutie a rýchlosť navíjačiek boli dynamicky riadené pomocou špecializovaných FAST modulov od spoločnosti Lenze.Dozvedieť sa viacTieto moduly umožnili automatické znižovanie napnutia pri zväčšovaní priemeru navíjaného materiálu, čím sa zabezpečila optimálna prevádzka stroja. Výpočet aktuálneho priemeru navíjania bol taktiež riadený týmito FAST modulmi, ktoré sú navrhnuté na presné riadenie navíjacích procesov. Moduly predstavujú pokročilé riešenie pre zložité riadiace úlohy v reálnom čase, čím zaisťujú vysokú efektivitu a spoľahlivosť celého systému.

Po preprogramovaní stroja a doladení mechanických nerovností, ktoré boli zistené počas generálnej opravy a testovania, sa celý proces navíjania a výmeny roliek stal efektívnejším. Navyše sa odstránilo krčenie materiálu, čo bolo hlavným problémom zákazníka.